By Anuj Monga, Research Director – Mobility

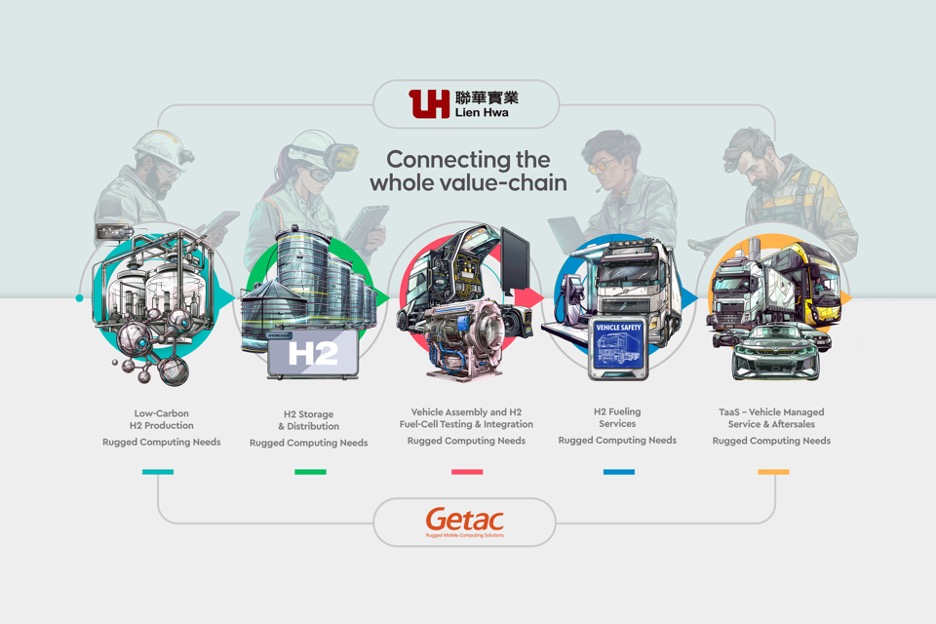

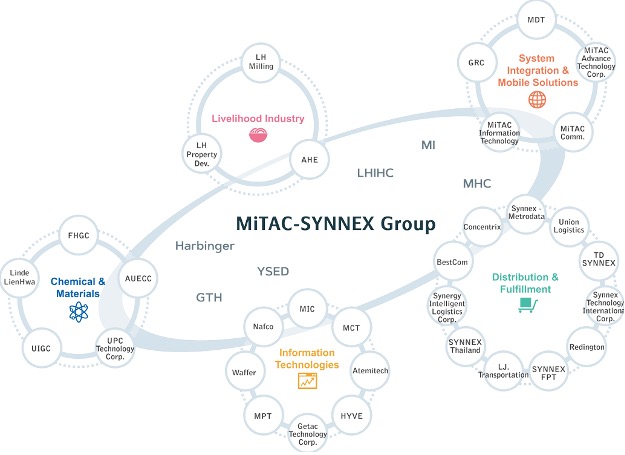

The Mitac-Synnex group in Taiwan, a conglomerate covering multiple sectors, including industrial gas, petrochemicals, IT, manufacturing and distribution, with consolidated revenues of US $84 billion in 2023, has recently created a new business division – LienHwa New Energy (LHNE). LHNE has been set up to consolidate the group’s efforts in decarbonization and is primarily responsible for driving coordinated efforts to build a hydrogen economy in Taiwan. Leveraging multiple companies within the group, including Linde LienHwa, Mitac, and Getac, the Lien Hwa group is strategically positioning itself in the hydrogen mobility value chain, spanning hydrogen generation and supply, fuel cell stack manufacturing, system integration, vehicle assembly, and aftersales service. Automotive continues to be a key focus for Getac Technology Corp and Getac’s rugged computing and digital software solutions have been designed to play a critical role across the value chain, both for partners and customers.

To learn more about the emerging hydrogen economy and the Mitac-Synnex group’s plans, Frost & Sullivan spoke with Toby Collins, Managing Director at Lien Hwa New Energy: “Through our long-standing decades joint venture with Linde, Linde LienHwa (LLH) affirms its extensive track record in providing industrial gases, including hydrogen, to various industries such as semiconductors and manufacturing, while leveraging the world-class capability of Linde. Linde LienHwa’s hydrogen product quality meets ISO14687 hydrogen fuel quality product specifications. Additionally, Linde’s hydrogen refueling stations (HRS) meet international requirements. The company remains focused on ensuring the highest levels of purity and quality to enhance user and consumer confidence, while establishing a clear and well-defined framework for applications.”

Frost & Sullivan: Currently, most hydrogen produced globally is from fossil fuels. What potential do you see for blue and green hydrogen in the future? Also, what are some of the challenges, say in terms of production costs or safety, that will need to be addressed?

Linde is the world leader in hydrogen production and is focused on both blue hydrogen from natural gas with carbon capture and, more recently, green hydrogen from renewable energy. In Taiwan, Linde LienHwa sees a transition towards green hydrogen by the end of the next decade as the country’s renewable energy portfolio grows to maturity, but at present are focused on low-carbon hydrogen production from natural gas. Production costs remain the biggest concern, with Taiwan yet to provide the same subsidies as offered by other governments. We believe, however, that we are on the right path, and leveraging our group’s strengths and assets, we will continue to strive towards further cost reduction by focusing on the localization of technologies and enabling a more sustainable and environmentally greener future for industries in Taiwan.

Beyond the group’s focus on hydrogen-fueled mobility, Getac continues to support organizations such as Linde LienHwa with rugged computing solutions used onsite by engineers for workforce management and inspection duties. Workplace conditions can be hazardous for typical computer solutions due to the potential of gas leaking into the atmosphere and the chance of a spark. Getac solves this through its certified technology for potentially explosive environments. This keeps the workforce safe and gives them peace of mind.

Infrastructure development will, of course, be a key enabler to the successful adoption of hydrogen-based mobility alternatives. Can you tell us a little about Linde LienHwa’s strategy related to expanding hydrogen fueling station networks?

Linde has already built over 200 fueling stations across the world, and Linde LienHwa has invested in the first demonstration hydrogen fueling station at one of its hydrogen production sites in anticipation of the new era of mobility. LLH has been awarded the project to supply the national petroleum company, CPC, its first HRS.

Do you intend to localize the hydrogen components for trucks as well as refueling infrastructure?

Yes, as mentioned earlier, our group’s recently set up division – LienHwa New Energy (LHNE) – is focused on bringing the first hydrogen vehicles, including passenger cars, trucks, and buses to Taiwan this year.

Localization is critical to being cost-competitive and to gaining government support. Here, LHNE is focused on the entire supply chain, bringing together the ecosystem from fuel cell stack manufacturing and system integration to vehicle assembly and distribution. While Linde LienHwa will manage the hydrogen supply side, LHNE will focus on the fuel cell integration and maintenance, and Getac will focus on delivering solutions and know-how around digitization, and look at ways by which workflows can be optimized throughout the value chain of production, technical, training, and aftersales support.

There has been considerable buzz over hydrogen mobility with several companies now active across both passenger and commercial vehicle markets. Hydrogen fuel cells are being used in both two-wheelers and four-wheelers. Hydrogen mobility is gaining traction in different sectors. New business models are emerging. Can you lead us through this fast-evolving space?

Getac is already the trusted vendor of many notable OEMs, serving their needs from a rugged mobile computing and solutions perspective within their research & development, manufacturing, logistics departments, and global dealerships and services networks. We have customers across the spectrum of vehicle types: two-wheelers, passenger cars, commercial trucks, heavy industry, and agricultural sector-related. We are excited to see how the mobility industry evolves with new entrants and modes of transport. Hydrogen mobility has already opened the door to many new providers and go-to-market strategies, such as Transport as a Service (TaaS). This is breaking the mold of traditional commercial vehicle ownership to reach an attractive Total Cost of Ownership (TCO) and achieve parity by bundling together vehicle costs, fuel costs, and service costs into one package over an extended period.

Can you tell us more about what Transport as a Service (TaaS) means?

Transport as a Service essentially refers to the entire ecosystem that will be required to deliver end-to-end services to customers. As mentioned earlier, we are fortunate to have a wealth of expertise and capabilities within the group. That said, we also need to work with our valued partners to provide a best-in-class approach for every segment of the value chain. For example, fuel cell providers, commercial vehicle chassis, available finance for the term, and dedicated platforms that provide our customers with exceptional aftersales service using the latest in AI to stay on top of the vast amounts of data that need to be validated and managed.

What changes do you think the adoption of hydrogen fuel cell vehicles will bring about for Getac, your group company, which has historically been a top supplier of rugged computing solutions to the OE and the aftermarket?

We see the adoption of hydrogen fuel cell vehicles as an opportunity to pool our group-wide capabilities and provide leading and sustainable solutions that better serve our customers. Thanks to the diverse nature of our group, we appreciate and understand the perspectives of all sides of the value chain, and we aim to be an exemplary model to the industry on how hydrogen can deliver value to our ecosystem. From Getac’s standpoint, we are sure that there will be a continued need for rugged computing for productivity gains and to control TCO. For example, several applications in hydrogen production, storage, and distribution focus on workforce health and safety or asset management in explosive environments. Or, during the hydrogen vehicle assembly and fuel cell testing process, rugged devices are often used for assembly line programming and line testing as well as parts logistics while mounted to automated guided vehicles. This is a perfect fit with our dedicated vehicle mounting solutions and software barcoding functionality. During the vehicle fueling stage of the value chain, Getac rugged tablets are mounted in the front of the connected truck and used by the delivery crew for route guidance, digital logging, and pre-vehicle inspection, while our driver safety application ensures that drivers are safe in motion and that there are no distractions during the trip. We will continue to offer Aftersales Technical and Intelligent Workflow solutions, such as AI scheduling and workshop management and the latest in vehicle health check software that serves as a duty of care to fleet customers, eliminating wasted time, and maximizing the opportunity to enhance the customer experience.

We are delighted that our recently formed New Energy Initiatives division is creating these kinds of opportunities, bringing together the strengths and resources of multiple companies within our group. By working together more closely, we are able to provide truly competitive and fully integrated solutions to the market and help drive efforts towards a Net Zero economy in 2050.

With inputs from Amrita Shetty, Senior Manager, Communications & Content –Mobility