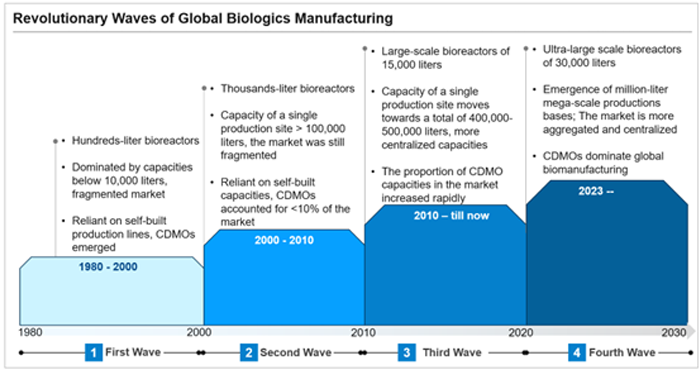

The global biomanufacturing capacity gap and budget constraints have ignited the “The Fourth Revolutionary Wave of Biologics Manufacturing”, with production sites expanding towards million-liter scales. In this context, Contract Development and Manufacturing Organizations (CDMOs) have become key players in global biomanufacturing. Initially, from 1980 to 2000, manufacturing relied on self-built systems with hundred-liter bioreactors, resulting in fragmented manufacturing capacity. As companies began to seek external R&D and production support, CDMOs emerged as a new force. Since then, the industry has experienced the second wave of development from 2000 to 2010, followed by a third surge from 2010 to the present. Bioreactor capacities, serving as the core of manufacturing, increased from hundreds to tens of thousands of liters, with single-site capacities now exceeding 100,000 liters. In 2023, BiBo Pharma, founded in Boston, USA, introduced a new generation of ultra-large production platforms. This includes a 30,000L (working volume) stainless steel bioreactor and a total volume exceeding 40,000 liters, marking a new era in biomanufacturing. BiBo Pharma is breaking capacity barriers and reducing antibody drug production costs from the international average of hundreds of dollars to just $10 per gram, offering disruptive solutions to global biopharmaceutical companies.

Source: Public Information, Frost & Sullivan Analysis

Part I: BiBo Pharma 1.0 : Reflecting on the Past – Originating in Boston, USA, and Navigating through the Global CDMO development Journey

As the biopharmaceutical era rapidly expands, the challenge of insufficient biomanufacturing capacity has become more pressing. BiBo Pharma’s growth closely aligns with industry trends, addressing the need for rapid expansion and cost efficiency of commercial production. In the increasingly competitive CDMO industry, BiBo Pharma continues to advance.

This success is due not only to their precise grasp of market opportunities but also to their breakthroughs in core biopharmaceutical industrialization technologies. Sailing from Boston, BiBo Pharma has been committed to the commercial production of biologics since its inception. The company independently designed and manufactured the ultra-large stainless steel bioreactors and pioneers a new generation of production models. In 2023, BiBo Pharma successfully completed the construction of a 30,000L single-tank ultra-large-production line, and in March 2024, it successfully commenced operations.

To meet the diverse demands of the biopharmaceutical market, BiBo Pharma developed a comprehensive technology platform for microbial fermentation, mammalian cell culture, gene therapy, and antibody-drug conjugates (ADC). This platform offers one-stop services from DNA to IND/BLA and large-scale commercial production.

To date, BiBo Pharma has offered CDMO services for more than 130 large molecule projects, excelling in mammalian cell culture, drug substance production, and formulation. Their operations adhere to international quality and management standards, solidifying BiBo Pharma’s position on the global CDMO stage after a decade of dedicated effort, and pioneering the next generation of CDMO models.

Part II: BiBo Pharma 2.0: Current Focus – Upgrading Strategies and Expanding Capabilities

//30,000L Capacity Advantage and Global First Delivery Advantage as an Industry Pioneer//

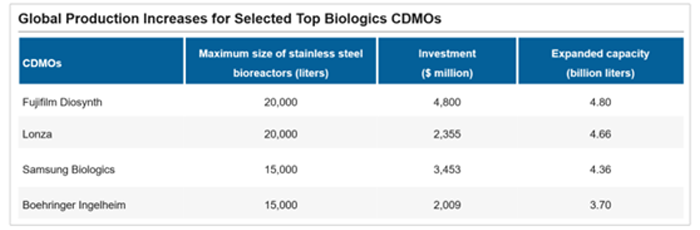

Driven by booming global demand for biologics, especially blockbuster drugs, more CDMOs with large-scale production capabilities are undertaking contract manufacturing to ensure a stable and cost-efficient supply. Major global CDMOs are expanding their large-scale commercial production capacities by focusing on the construction of large-scale stainless steel bioreactors. The future direction involves advancing from the current 15,000L reactors to fourth-generation ultra-large-scale production technologies.

Source: Corporate News, Corporate Websites, Frost & Sullivan Analysis; Only publicly disclosed capacity expansion and investment plans are counted, as of April 2024

BiBo Pharma is the first and only CDMO to deliver a new generation of ultra-large stainless steel bioreactors with a maximum working volume of 30,000L per tank. This is an engineering scale-up of over 2.5 times compared to the current 15,000L (total volume) standard in large-scale biopharmaceutical production. BiBo Pharma leverages economies of scale and cost-sharing to offer a potential solution to reduce costs on the basis of ensuring independently designed core equipment and a controllable supply chain. With the successful deployment of the 30,000L bioreactor, BiBo Pharma has completed its comprehensive production line strategy. The BiBo P03 plant now features GMP production lines for 2,000L, 10,000L, and 30,000L microbial and mammalian cell cultures, offering enhanced flexibility to meet diverse client needs.

PanFlex®-Engineering: Breaking Through the “Quality-Cost-Efficiency” Triangle

The 30,000L production line of BiBo Pharma is housed in a 24-meter-high plant covering 65,000 square meters. It includes over 200 kilometers of process piping, 20 kilometers of cleanroom air ducts, nearly 500 kilometers of cables, and 11 million parts with hundreds of core devices. Each line features over 5,000 critical process nodes.

In the construction of the 30,000L production line, BiBo Pharma utilized its PanFlex®-Engineering and PanFlex®-Operation systems to address obstacles such as stainless steel reactor construction, high initial investment, and long construction cycles.

The conventional factory construction process adopts an engineering design model that proceeds from the top level down to the lower levels. PanFlex®-Engineering employs a “Process is King” strategy, using standardized units to reverse-engineer a complete factory. As a result, PanFlex®-Engineering system transcends the impossible triangle of “quality-cost-efficiency.” Remarkably, it took less than 18 months from the project’s initiation in January 2022 to delivering a 30,000L ultra-large production platform by June 2023, roughly half the time and cost of similar projects worldwide. In addition, the 30,000L platform passed quality audits from the U.S., EU, and Chinese clients. Leveraging its PanFlex®-Operation system, Bibo Pharma achieved a “Right on First Time” in March 2024 when the platform was put into operation with a 100% success rate in subsequent production.

Grand-CHO Platform: A “Three-in-one” Approach to Innovation

Over the past decade, BiBo Pharma has focused on developing a “Three-in-One” approach to innovation——Grand-CHO Platform, that involves advances in cell line development, process research, and production technology for ultra-large-scale platforms.

Grand-CHO platform improves cell line expression and stability, optimizes commercial production processes of different scales, and offers other benefits. The second-generation Epic-CHO cell line achieves a high expression level of 10 g/L at the mini-pool stage and offers more than double the stability of leading international cell lines, laying a solid foundation for large-scale production.

Grand-CHO technology enables high-density and large-scale cell storage, while seamlessly integrating a 3,000L N-1 perfusion process and a 30,000L intensified Fed-batch production process. Compared to traditional methods, Grand-CHO technology reduces production cycle time by 30%, doubles the yield per fermentation volume, and cuts restart time for 30,000L projects from 60 days to 30 days. Grand-CHO technology, integrated with the 30,000L ultra-large-scale production line, is fundamentally transforming the overall production efficiency of biopharmaceuticals.

Pulse Continuous Manufacturing (PCM)

The combination of BiBo Pharma’s PanFlex®-Engineering and Grand-CHO technology has led to a groundbreaking production model — Pulse Continuous Manufacturing (PCM). Unlike traditional batch processing or the frequently mentioned continuous manufacturing, PCM releases a single high-volume batch upstream, such as 60,000 liters per pulse (60kL/P). It then processes multiple downstream batches continuously based on each unit’s operation time. PCM significantly improves production efficiency, boosting overall line efficiency by 50% to 300%. PCM’s success is driven by the interconnected equipment enabled by PanFlex®-Engineering. Additionally, BiBo’s P03 plant has implemented an automated process control system (PAS) that enables full digital integration across the facility, making the execution of the PCM model more efficient and seamless.

Technology Integration Drives Reduction of Antibody Drug Production Cost to $10 per Gram

After over 40 years of evolvement, the biopharmaceutical industry is now focused on cost optimization and manufacturing stability. Advancements in innovative drugs, including antibody drugs, cell and gene therapies (CGT), and antibody-drug conjugates (ADC), are driving the increasing demand for clinical-level R&D and production. Intensifying market competition within the biopharmaceutical industry makes cost control a growingly crucial factor for market entry. Meanwhile, the expiration of numerous key patents has led to a shift from innovator biologics to biosimilars. Compared to innovator biologics, biosimilars comes with much stricter requirements of production cost control.

To solve the constraints of biopharmaceutical production costs, BiBo Pharma has made notable advancements over the past decade. The primary initiative is the international breakthrough of the first-ever 30,000L single-tank ultra-large-scale production line, which leverages economies of scale to reduce product costs. The company is now expanding to a million-liter production base. Integrating PanFlex®-Engineering, Grand-CHO technology, and a pulsatile continuous production mode, BiBo Pharma balances cost-efficiency, flexibility, and stability. Through individual breakthroughs and diverse collaboration, these advancements enhance efficiency, optimize facility use, and reduce antibody drug production cost from hundreds of dollars to $10 per gram.

Source: Public Information

An Engineering and Technical Service Provider

BiBo Pharma has launched the pioneering “Blue Whale Program,” a financial risk-free manufacturing solution powered by the PanFlex® system. This program offers tailored production line construction services to global clients. In conventional biopharmaceutical operations, building a production line for a product in late-stage clinical trials involves high investment costs and long construction times. Additionally, there are risks of underutilization or insufficient capacity due to uncertainties in product approval and market success.

The “Blue Whale Program” addresses these challenges by significantly reducing both construction costs and timelines by 50% with the support of the PanFlex® system. This allows clients to postpone capital expenditure decisions from Phase I/II to Phase III of clinical trials, giving them more time to make informed investment choices. Additionally, the program provides a risk reduction feature: fees paid by clients are refundable regardless of whether the product succeeds in the market. This effectively offers additional insurance for commercialization and mitigates risks in the R&D and production phases, supporting the successful industrialization of innovative products.

BiBo Pharma has recently secured orders for its customized engineering solutions. In April 2024, 89bio, the holder of Pegozafermin for metabolic dysfunction-associated steatohepatitis (MASH), announced that it has reached an agreement with BiBo Pharma to build a production line at Lingang Base to support the commercialization of this drug candidate. Under the collaboration agreement, 89bio will pay BiBo Pharma an aggregate of $135 million toward the construction of the production facility.

Part III: BiBo Pharma 3.0: Shaping the Future – Establishing Comprehensive Technology Industry Advantages and Leading the Next Chapter

Capacity planning is crucial for a CDMO to carry out its business. BiBo Pharma establishes an intensive production model by focusing on its 30,000L ultra-large production line and expanding the production capacity towards million-liter level in a single base. This model also underpins BiBo Pharma a diversified, full-technology platform offering one-stop CDMO services. With its Boston R&D center and global production capabilities, BiBo Pharma delivers high-quality services adhering to international standards. BiBo Pharma utilizes its unparalleled industry advantages to empower the global biopharmaceutical companies by reshaping the cost structure of biologics. The company aims to reduce antibody drug production cost to $10 per gram, enhancing patients’ affordable access to high-quality biologics.

Additionally, the “Blue Whale Program” expands BiBo Pharma’s established engineering solutions, reaching more clients with commercial production needs. These capabilities and advantages position BiBo Pharma as the best solution for global pharmaceutical companies in the future.